As we all know, with the rapid development of e-commerce logistics, medical chemicals, textiles and clothing, trade circulation, rail transit, auto parts, military supplies, furniture and household appliances, hardware and building materials, equipment manufacturing, refrigeration and other different fields, the demand of customers and businesses in different industries for their storage is also increasing. In order to make storage products more suitable for the industry, The traditional fixed shuttle car can no longer meet the requirements of handling different size bins. At present, Hebei Walker Metal Products Co., Ltd., under its own brand HEGERLS, has launched a variety of shuttle models, including single/double depth shuttle cars, clip on telescopic fork shuttle cars, and anti-static shuttle cars. These models can meet the needs of special industries. Among them, the new clip on four-way shuttle car launched by HEGERLS, an independent brand of Hebei Walker, can solve the problem of high-density storage of boxes of different sizes.

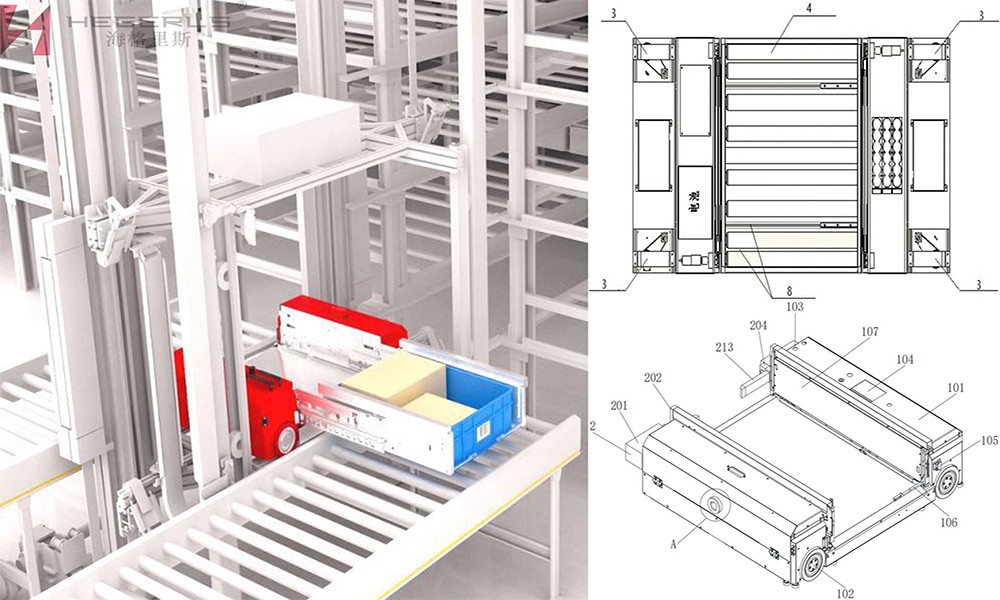

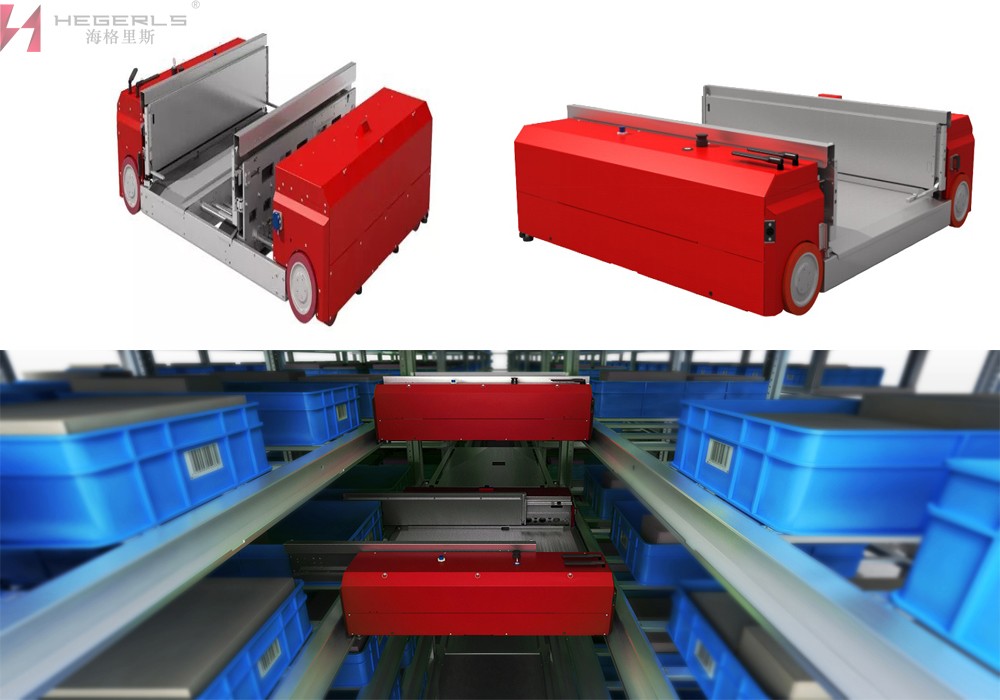

The clip on four-way shuttle car owned by HEGERLS breaks the limitations of the past that it can only access fixed bins. It can adjust the distance of the telescopic fork by sensing the size of the detection box, so as to achieve the telescopic clamping of bins of different sizes. After identifying and locating goods, the HEGERLS clip on four-way shuttle can automatically adjust its own clip on telescopic fork according to the size of the processed goods, which is characterized by fast operation, stable operation and efficient loading. Together with HEGERLS high-speed elevator and other equipment, it can further improve the degree of automation, make the process more flexible, improve the overall capacity and throughput of the warehouse, and greatly improve the operating efficiency. The existing clamping four-way shuttle car of HEGERLS can precisely clamp the size of the material box between 250MM and 800MM, and its running speed can be up to 5M/S. In addition, the HEGERLS clip on four-way shuttle also solves the problem of reversing, and it can also carry out flexible planning and overall planning between multi-layer boxes. Such operation mode greatly improves the operation efficiency of the whole car body.

The biggest difference between HEGERLS clip on four-way shuttle and other shuttle brands in the industry is the power supply mode. The power supply mode of shuttle bus is also the most concerned problem for customers since Hebei Walker undertook various large, medium and small storage projects. The power supply mode adopted by HEGERLS clip on four-way shuttle is super capacitor. The super capacitor power supply mode can realize fast charging and fast sending. After charging for 10s, it can meet the operation requirements of the four-way shuttle bus for 3MIN. During the operation of the four-way shuttle bus, it can also realize the function of kinetic energy recovery.

Of course, some customers will ask whether the core components are surplus? Will there be power failure of core components?

For this point, Hebei Walker has considered this problem for customers in advance. Hebei Walker has R&D centers at home and abroad, and the R&D and design of its own brand HEGERLS has reached the leading level. The core components needed are all developed and produced using international standards, which effectively avoids the potential risks brought by the production of customized storage supplies for enterprises.

The HEGERLS AG four-way shuttle car is a very flexible, highly expandable and safe intelligent car, which can realize automatic docking, picking up, handling and other operations. The upper computer sends instructions through WIFI to send the car to the designated place to pick up goods and transport them to the target point. Its biggest characteristics are: laser reflector guidance and natural contour guidance, strong adaptability and low construction difficulty; 360 degree omnidirectional movement, dual steering wheel structure chassis, stronger space adaptability; 360 degree blind angle free laser detection and obstacle avoidance can realize system scheduling and task allocation, with high operation efficiency; Backed chain conveyor can automatically dispatch the width, perfect to adapt to a variety of on-site chain conveyors; It has strong flexibility and expandability, high stability, low investment cost and low management difficulty. At the same time, the “3D visual operation monitoring platform” of the four-way shuttle can collect the plant data in real time and intelligently monitor the plant conditions; What is more worth mentioning is that lightweight solutions can be generated for equipment conditions for managers to make accurate maintenance plans.

Hebei Walker has provided customers with one-stop professional warehousing solutions from consulting, planning, design, research and development to later operation coaching. In terms of its after-sales service, Hebei Walker promises to respond to customers’ needs in a timely manner within 24 hours, and pay long-term attention to customers’ use of storage shelves and storage equipment under HEGERLS, so as to ensure the efficient operation of customers’ business, and upgrade the system from time to time according to customers’ business needs, so as to ensure better adaptation to users’ needs. Hebei Walker said that in the future, it will continue to innovate the shuttle bus, show users its features of richer functions, more comprehensive performance and more powerful systems, and provide more diversified intelligent warehousing solutions for various industries with highly standardized services and rich experience in intelligent warehousing.

Post time: Jan-09-2023