With the rapid development of the economy and the continuous progress of science and technology, there has been a qualitative leap in the development of modern warehousing and logistics industries. The integration of technology into the research and production of warehousing has promoted the emergence of automated warehousing equipment. When it comes to automated warehousing equipment, we cannot ignore the intelligent transportation robot, the four-way shuttle car. The four-way shuttle car is the core of the warehousing system, and is an intelligent transportation robot that works on the track. It can achieve material management, counting, and placement under the control of a computer system.

As a system, the four-way shuttle needs to work as a complete system with shelves (tracks), elevators, conveyor systems, communication systems, and charging systems. Of course, software systems related to management,

monitoring, scheduling, and control are also essential. At present, the design, procurement, and construction of the four-way shuttle vehicle shelf system have become the ideal choice for many large and medium-sized enterprises. Based on the huge market space, Hebei Woke Metal Products Co., Ltd. will optimize the design plan according to the specific characteristics of each enterprise's warehousing, and provide the ideal HEGERLS four-way shuttle vehicle shelf system.

Hebei Woke Metal Products Co., Ltd. is a comprehensive enterprise dedicated to the planning, design, manufacturing, installation, and consulting services of warehousing and logistics systems and automated three-dimensional warehouse systems. Our company adheres to tradition and takes a global perspective, actively introducing and absorbing the advantages and characteristics of advanced logistics equipment structural forms and design ideas, and always occupies a favorable position in the field of warehousing logistics equipment technology.

Hebei Woke Metal Products Co., Ltd. also develops its own brand HEGERLS, which produces products related to aisle stackers, shuttle cars, conveyors, shelves, sub and sub car systems, software, and non-standard workstation appliances. In order to adapt to the needs of domestic and foreign market competition, continuously improve the company's quality and environmental management level, and enhance the product quality and

environmental management awareness of all employees, Hebei Woke strictly follows the ISO9001, ISO14001, and ISO45001 certification system, namely "quality, environment, and health" ISO certification, always pursuing advanced international management models, continuously absorbing advanced technologies from the domestic and foreign logistics industry, and introducing On the basis of digesting advanced technologies both domestically and internationally, we independently develop new technologies and products based on the actual situation of domestic enterprises. Continuously innovating and advancing, Hebei Woke has always been at a high level in the domestic logistics industry.

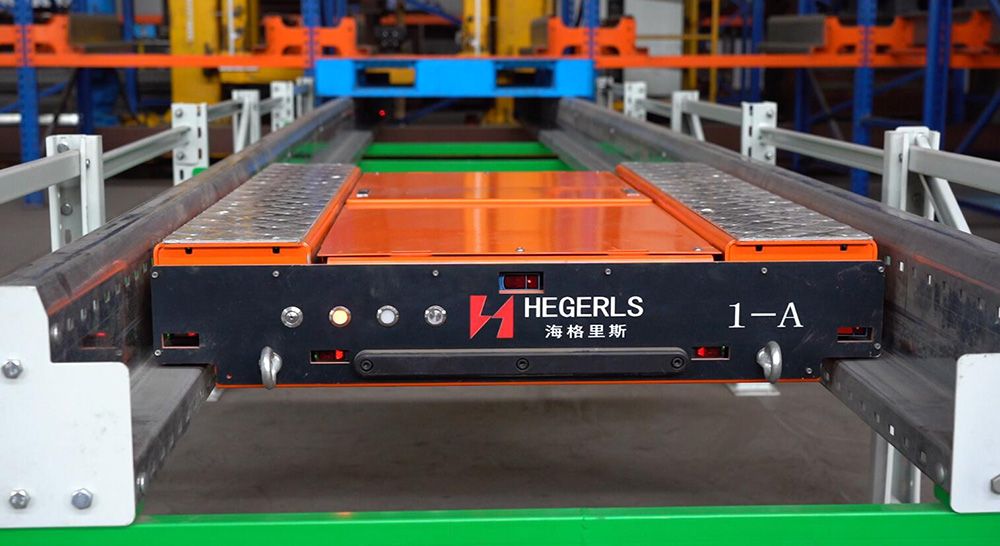

Hebei Woke's core product HEGERLS four-way shuttle system

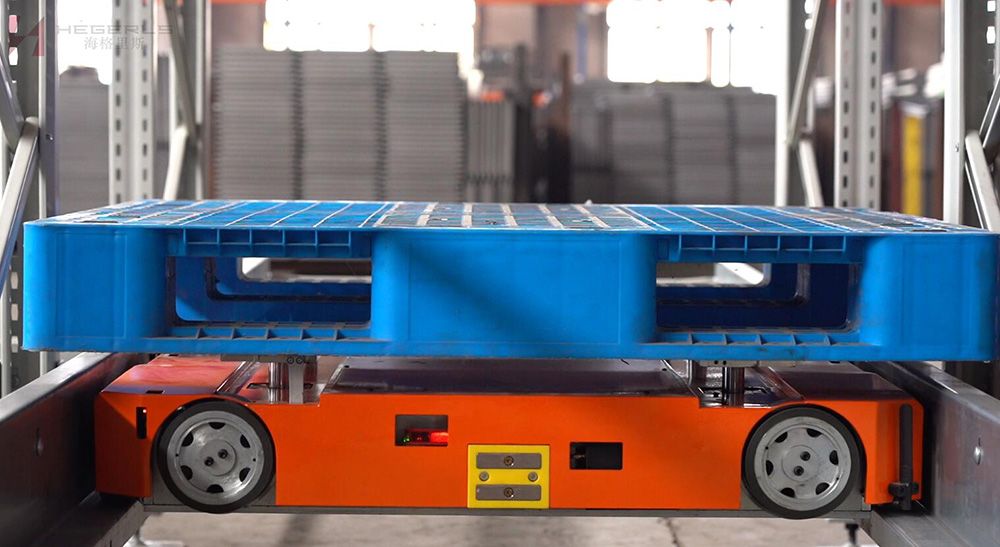

The application of four-way shuttle racks has completely changed the concept of dense warehousing systems, and can even be said to be a disruption. From the application of simple shuttle cars to the shelf systems of parent-child shuttle cars and four-way shuttle cars, its development trajectory has always revolved around the aspect of dense warehousing. Compared to traditional automated warehouse systems, storage density can be increased by 30% to 50% depending on different solutions. The biggest advantage is that the HEGERLS four-way shuttle truck shelves can be arranged in almost any space, which is an advantage that automated warehouses cannot match. Although the automated warehouse system also adopts dual deep storage technology to improve storage density, the storage density and space requirements are far lower than those of four-way shuttle shelves.

Performance advantages of the HEGERLS four-way shuttle

1) Dense shelves

Compared with traditional warehouse shelves, four-way shuttle truck shelves can be designed to be larger and denser because the four-way shuttle truck has high flexibility and is not limited by the size of warehouse space. Moreover, the dense four-way shuttle truck shelves greatly improve the speed of goods handling, increase the flow of goods in the warehouse, and overall improve the warehouse's warehousing efficiency to meet people's needs.

2) More intelligent

The four-way shuttle truck rack adopts advanced intelligent control technology, which can achieve autonomous navigation and cargo handling, saving a lot of manpower and

material resources. In addition, the intelligent design reduces errors caused by human operation factors, effectively ensuring the normal and stable operation of the four-way shuttle truck rack.

3) Strong collision resistance

The overall structure of the four-way shuttle truck rack adopts a brand new design, which significantly enhances its anti-collision performance. This is because the four-way shuttle truck rack is prone to bumps during normal operations. If the equipment's anti-collision performance is not strong, it can easily cause damage to the body and affect the efficiency of warehouse operations. However, the four-way shuttle truck rack has good anti-collision performance, which can effectively avoid this situation.

4) Good seismic performance

The structural design of the four-way shuttle truck rack is more reasonable and stable compared to traditional warehouse racks, which greatly improves its seismic performance. In the actual operation of the warehouse, there is significant vibration when handling goods, but the good seismic performance of the four way shuttle truck shelves can effectively avoid this, allowing the four way shuttle truck to operate stably and efficiently

5) Wide application range

The four-way shuttle truck rack adopts automatic shrinkage technology, which can adjust the rack according to the working environment and storage of goods. This feature greatly improves its application range and can play its role in various working environments.

Post time: Jun-15-2023