With the use efficiency of storage space in the modern warehousing and logistics industry and the emphasis on the management concept of minimizing the storage operation cost, the high-density automatic warehouse layout is carried out. The use mode of the box-type four-way shuttle car plays an important role in the automated three-dimensional warehouse, which greatly improves the throughput rate in the warehouse, and the intelligent shuttle car completes the roadway operation, and develops rapidly in the direction of unmanned, automated and intelligent, To meet the growing demand of users.

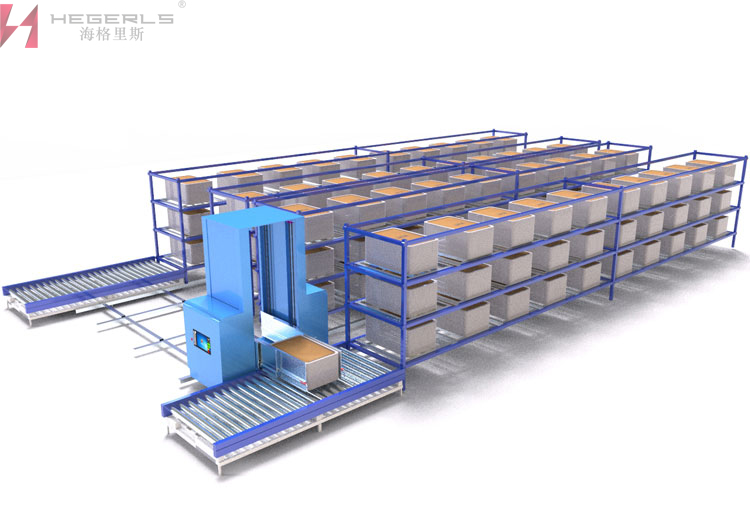

Enterprises that have been put into use should know that the more complex aspects of the bin type four-way shuttle system are the control and scheduling, order management, route optimization algorithm, etc. of the four-way shuttle system. Therefore, the difficulty coefficient in the project implementation process is also large, and there are relatively few suppliers who can make this system. In recent years, Hebei Walker Metal Products Co., Ltd. (independent brand: HEGERLS) has also found these technical problems related to the four-way shuttle through the feedback of enterprise customers and the specific conditions of each project in accordance with the warehousing projects undertaken by large, medium and small enterprises for more than 20 years, and has carried out continuous exploration, research and innovation, We have developed and produced a set of HEGERLS box-type four-way shuttle system suitable for different industries, different fields and different enterprises. The main body of work has also changed from rack storage to robot+rack. A new system integrated logistics storage system is formed by the storage system integrated with rack+shuttle car+elevator+picking system+control software+warehouse management software. The unit bin cargo+light four-way shuttle car is used as the carrier for the bin type four-way shuttle car to change lanes for operation and storage of goods.

The box-type four-way shuttle car is different from the traditional shuttle car

The box-type four-way shuttle car can solve the problem that the ordinary shuttle car can not move laterally. At the same time, it can also use the cam mechanism for fast and accurate reversing function. In addition, 80% of the body parts of the box-type four-way shuttle are made of aluminum alloy, which can not only meet certain requirements in strength, but also reduce the body weight to 120KG. In addition, the bin type four-way shuttle car is equipped with a facility fork. The entire fork is designed in a modular way, with the characteristics of rapid maintenance and replacement. The fork can also be used for single and double deep storage space access. Its design mainly uses aluminum plate to cooperate with the slide rail. The steel wire drive slide rail is used to achieve the function of the fork to access the bin. The steel wire fixing mechanism can be tensioned and adjusted to ensure the reliability of the fork operation. The swing of the fork is solved by shaft transmission. The fork motor and detection switch are installed at the front and rear of the four-way vehicle, so that the fork transmission does not transmit power like the ordinary shuttle vehicle. The detection switch and drag chain are installed, which greatly reduces the fork height.

The HEGERLS bin type four-way shuttle system is an intelligent transportation equipment with high space utilization and flexible configuration. It can not only improve logistics efficiency, but also greatly save manpower. At present, it has broad application prospects in many industries, especially in the storage center with large storage capacity and SKU, as well as the warehouse with irregular, large length and width, or high or small efficiency of warehousing and warehousing. It has high flexibility, is suitable for high-density shelves, and can realize any shuttle. It can be flexibly adjusted according to the investment plan, and can realize the goods layer change in combination with the special layer change elevator. The box-type four-way shuttle car runs smoothly, accelerates quickly, and stops accurately; Short charging time, long running and standby time, maximum speed 4.0m/s, rated load 50kg. High-efficiency and energy-saving motors are mostly used in the driving part of the HEGERLS four-way shuttle car, and the energy released during the deceleration of the four-way car is collected and reused by using the self-developed energy recovery technology to reduce the energy consumption of the four-way car. Of course, when necessary, we can also set up the dispatching mode of operation fleet to cope with the peak of the system, so as to solve the bottleneck of warehouse entry and exit operations and improve the efficiency of entry and exit. Not only that, but also by reducing the weight of the handling equipment, the requirements of reducing the energy consumption and handling costs can be achieved.

How does the HEGERLS bin type four-way shuttle work?

◇ Cargo handling operation

*The HEGERLS four-way shuttle car travels in four directions in the shelf according to the task path, and stores and transports goods to the conveyor in front of the warehouse.

*The HEGERLS high-speed composite elevator equipped with facilities moves up and down in the vertical direction at the end of the conveyor in front of the depot to connect and transport goods to the ground transportation system or other connecting equipment.

◇ Layer change operation

*The HEGERLS four-way shuttle car drives into the high-speed composite hoist according to the system command and carries out the layer change operation.

*Then the four-way shuttle car is carried by the high-speed elevator and moves up and down in the vertical direction to change the operation layer.

Biggest advantages of HEGERLS box-type four-way shuttle

Standardization and serialization: The HEGERLS bin type four-way shuttle car is suitable for 600 * 400 standard boxes, and its load capacity range is 50kg. Two aspects need to be considered in the future system series: size and fork type.

Hoists: from the structural point of view, they can be divided into hoists with cars and hoists without cars. The belt elevator is mainly used for changing layers of shuttle cars; The lifting capacity of the elevator without car is very strong. At the same time, the dual-station elevator can also be used, and the lifting capacity can be up to 250~500 times/hour.

Load transfer: The bin type shuttle car is much more flexible. The simplest way is to use the fork, and of course, the fork with double depth can also be used. Another advantage of HEGERLS box-type four-way shuttle car is that when the unit becomes smaller and lighter, it can also be transferred in many ways.

Speed and acceleration: the speed of the trolley can be as high as 5 m/s in terms of the improvement of operation efficiency; In terms of clamping device, the acceleration of the trolley can be as high as 2m/s2. Compared with the elevator, the lifting speed can be as high as 4~6m/s to match the efficiency of the whole system.

Maintenance: As mentioned earlier, the HEGERLS bin type four-way shuttle is relatively complex. It needs to avoid entering the shelf as much as possible, and the possibility of entering the shelf should also be considered in the design.

Cost-performance ratio: Because of its complex structure and high cost, it needs to be continuously optimized to reduce costs and improve cost-performance ratio.

Hebei Walker has also solved many warehouse storage problems for major enterprises in recent years because of its unique HEGERLS four-way shuttle intelligent intensive storage system and special solutions. HEGERLS four-way shuttle intelligent dense storage system is composed of horizontal conveying system, shelf system, four-way shuttle, fast vertical elevator and WMS/WCS management and control system. Because the single machines and units of Hagrid are interconnected with each other under the support of wireless network, only under the dispatching of the WMS WCS upper management and control system can the warehousing and outbound work of goods be completed in response to each other. Don’t underestimate such a system. It is precisely because of such an automatic intelligent system that the HEGERLS bin type four-way shuttle car automatic stereoscopic library has been widely used in e-commerce logistics, refrigeration, textile shoes and clothing, auto parts, hardware and building materials, equipment manufacturing, military supplies and other industries.

Post time: Jan-11-2023