With the rapid development of modern technology, the storage requirements of customers will also change. In the long run, large enterprises will generally consider automated three-dimensional warehouses. Why? Up to now, the automated three-dimensional warehouse has a high space utilization rate; It is convenient to form an advanced logistics system and improve the production management level of the enterprise; Reduce labor intensity and improve production efficiency; Reduce the backlog of inventory funds; It has become an indispensable technology for enterprise logistics and production management, and has been paid more and more attention by enterprises. Of course, enterprises that have used automated three-dimensional warehouse shelves have heard of separated warehouse shelves and integrated warehouse shelves? So how to use these two kinds of three-dimensional warehouse shelves? The following hegerls storage shelves will take you to understand!

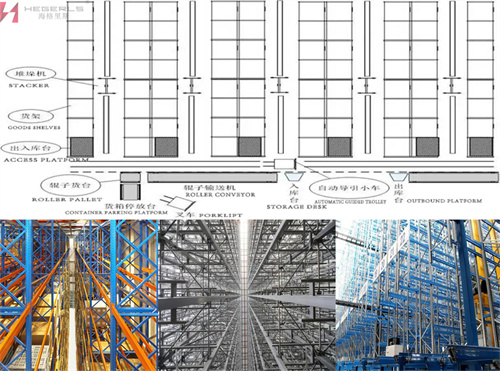

The automatic three-dimensional warehouse is composed of a rack system, a roadway rail stacking crane, a conveying system, an automatic control system, a computer warehouse management system and peripheral equipment. The use of three-dimensional warehouse equipment can realize the rationalization of high-level warehouse, the automation of access and the simplification of operation; Automatic three-dimensional warehouse is a form with high technical level at present. The main body of the automated three-dimensional warehouse is composed of shelves, roadway type Stacking Cranes, entry (exit) worktables and automatic entry (exit) and operation control systems. In fact, the most important thing about the shelves of the automated three-dimensional warehouse is that they belong to the automated three-dimensional warehouse system (as / RS automated storage and retrieval system), which is a system that automatically stores and takes out goods without direct manual processing. There are three automatic control modes of three-dimensional warehouse: centralized control, separate control and distributed control. Distributed control is the main direction of international development. Three-level computer distributed control system is usually used in large-scale three-dimensional warehouses. The three-level control system is composed of management level, intermediate control level and direct control level. The management level manages the warehouse online and offline; The intermediate control level controls the communication and flow, and displays real-time images; The direct control level is a control system composed of programmable controllers, which performs single-machine automatic operation on each equipment, so that the warehouse operation can be highly automated.

The rack structure of the automated three-dimensional warehouse is as follows:

1. High level shelf: steel structure used to store goods. At present, there are two basic forms of welded shelves and combined shelves.

2. Pallet (container): an appliance used to carry goods, also known as a station appliance.

3. Roadway stacker: equipment used for automatic access to goods. According to the structural form, it is divided into two basic forms: single column and double column; According to the service mode, it can be divided into three basic forms: straight, curve and transfer vehicle.

4. Conveyor system: the main peripheral equipment of the three-dimensional warehouse, which is responsible for transporting goods to or from the stacker. There are many kinds of conveyors, such as roller conveyor, chain conveyor, lifting table, distribution car, elevator, belt conveyor, etc.

5. AGV system: i.e. automatic guided trolley. According to its guiding mode, it can be divided into induction guided car and laser guided car.

6. Automatic control system: the automatic control system that drives the equipment of the automatic three-dimensional library system. At present, the field bus mode is mainly used as the control mode.

7. Inventory information management system (WMS): also known as central computer management system. It is the core of the fully automated three-dimensional library system. At present, the typical automatic three-dimensional library system uses large-scale database system to build a typical client / server system, which can be networked or integrated with other systems (such as ERP system).

So what is the separated warehouse shelf?

Separated warehouse shelves, that is, buildings and three-dimensional shelves are not connected as a whole, but built separately. Generally, after the building is completed, three-dimensional racks and related mechanical equipment are installed in the building according to the design and planning. The shelves of the separated three-dimensional warehouse can not form permanent facilities, and can be reinstalled and technically modified as required, so it is more mobile. Generally speaking, the construction cost is high due to separate construction. The separated three-dimensional warehouse shelf is also suitable for the transformation of the old warehouse.

Characteristics of separated three-dimensional warehouse shelves:

1) Save the floor area of the warehouse

Since the automated three-dimensional warehouse adopts the assembly of large storage shelves, and the automated management technology makes it easy to find the goods, the construction of the automated three-dimensional warehouse occupies a smaller area than the traditional warehouse, but the space utilization rate is large. In some other countries, improving the utilization rate of space has become an important evaluation index for the rationality and progressiveness of the system. Today, when energy conservation and environmental protection are advocated, automated three-dimensional warehouse shelves have a good effect in saving land resources, and will also be a major trend in the future development of storage.

2) Improve the level of warehouse automation management

The automatic three-dimensional warehouse uses the computer to carry out accurate information management of the goods information, reducing the errors that may occur in the storage of goods and improving the work efficiency. At the same time, the three-dimensional automated warehouse realizes motorization in the transportation of goods in and out of the warehouse, and the handling work is safe and reliable, reducing the damage rate of goods. It can also provide a good storage environment for some goods with special requirements for the environment through special design, and also reduce the possible damage when handling goods.

3) Form an advanced production chain and promote the development of productivity

Professionals pointed out that because of the high access efficiency of the automated three-dimensional warehouse, it can effectively connect the production links outside the warehouse, and form an automated logistics system in the storage, thus forming a planned and organized production chain, which greatly improves the production capacity.

What is an integrated warehouse shelf?

The integrated warehouse is also known as the integrated three-dimensional warehouse, and the warehouse rack is integrated. The three-dimensional shelf is integrated with the building. The three-dimensional shelf cannot be disassembled separately. This kind of warehouse is the support structure of the high-rise shelf and building warehouse, which forms a part of the building. The warehouse is no longer provided with columns and beams. The roof is laid on the top of the shelf, and the shelf also functions as a roof truss, i.e. the warehouse shelf is an integrated structure. Generally, the overall height is more than 12M, which is a permanent facility. This kind of warehouse has light weight, good integrity and good earthquake resistance. The cost can be saved to a certain extent.

What are the characteristics of integrated warehouse shelves?

1) Effective use of space

The integrated warehouse rack can effectively use space, realize the integration of the warehouse and rack, can withstand large wind load, and its height is high, which can effectively and reasonably use space. At present, the height of the highest integrated automated warehouse in China has reached 36m.

2) There is no structural column in the warehouse

For the scheme design of the automatic warehouse, the most taboo is the structural column in the warehouse. Its existence increases the space occupied by the shelves of the three-dimensional warehouse. If the column is in the cargo compartment, the entire cargo space will be wasted; For example, the three-dimensional space is between the rack rows, which increases the width of the three-dimensional warehouse.

3) Good seismic resistance

Since the integrated automatic warehouse realizes the integration of the storage rack, the shelf, the room rack, the C-shaped steel, the steel structure, the foundation and the color steel plate in the front and rear areas of the warehouse form a whole, and its seismic resistance is greatly improved.

4) Equipment in the library

The installation and construction of equipment in the integrated warehouse rack warehouse is convenient and fast. The sequence of the integrated automatic warehouse is: Foundation – rack installation – stacker installation – color steel plate enclosure, which is different from the installation in the plant and makes the lifting of large parts of the stacker more convenient.

5) Uniform stress

The foundation is uniformly stressed and the foundation design is relatively simple. However, the separated light steel warehouse has many H-shaped steel columns, so the foundation under the columns must be specially designed.

The separated warehouse shelf has the following advantages compared with the integrated warehouse shelf:

1) Because it has nothing to do with the building, the warehouse shelves closely connected with the production process can be built by using the corner inside the workshop, and the existing buildings can also be transformed into warehouse shelves;

2) When the ground pressure of the existing building is 3 tons / m2 and the unevenness is 30-50 mm, the separated warehouse shelves can be built without treatment on the ground; However, the foundation and ground treatment of the integrated warehouse shelves are more complicated, accounting for about 5-15% of the total cost;

3) The construction period is short. The construction period of the integrated warehouse shelf is generally 1.5-2 years, but the construction period of the separated warehouse shelf is shorter;

4) Mechanical equipment such as separated warehouse shelves, lane type Stacking Cranes and automatic control are easy to be standardized and serialized, which can realize mass production and achieve the effect of low price. Therefore, the development of small-scale separated warehouse shelves abroad is faster than that of large-scale integrated warehouse shelves, accounting for about 80% of the total. With the development of science, technology and productivity, the storage rack technology of large-scale integrated warehouse has further developed towards systematization, automation and unmanned.

Hegerls warehousing is a professional company dedicated to the development, research, design, production and installation of modern logistics technology. It has strong technical force and advanced production equipment, as well as mature living technology and perfect quality assurance system. The company has a number of production lines such as cold and hot coil slitting equipment, general profile rolling mill, shelf rolling mill, CNC steel strip continuous stamping, automatic welding, electrostatic powder automatic spraying and so on. The shelf technology is imported from abroad and has the characteristics of good assembly, large bearing capacity and strong stability. Cold and hot steel plates shall be used for shelves. Shelves and storage equipment shall be manufactured and tested in strict accordance with relevant national standards and enterprise standards, and a complete product quality system and installation and after-sales service team shall be established. Haigris storage rack manufacturer has been committed to the manufacturing and development of storage equipment for many years. The product types include: automatic three-dimensional warehouse, shuttle shelf, gravity shelf, press in shelf, attic platform shelf, heavy shelf, beam shelf, through shelf, wire bar shelf, fluent shelf, medium and light shelf, iron tray, plastic tray, logistics trolley, auto parts trolley, plastic turnover box, smart fixed frame Foldable storage cage, warehouse isolation wire mesh, hydraulic lifting platform, manual truck and other logistics storage shelves and storage equipment. Thousands of large warehouses have been completed for various well-known enterprises in China. The products have been involved in many industries, such as aerospace, logistics, medical, clothing, electronics, coating, printing, tobacco, cold chain, mechanical equipment, hardware tools, building materials, chemical industry, printing, process toys, textiles, home furnishings, instruments and meters, metallurgy and minerals, food, security equipment and other industries.

Post time: Aug-08-2022