With the development of high and new technology, people’s demand is constantly increasing. At the same time, as an important part of modern warehousing and logistics center, automated warehouse technology is constantly iterative, and four-way vehicles and stackers are commonly used automated warehouse solutions today. The two types of equipment have their own characteristics, so there will be differences in application. How should enterprises choose the appropriate warehousing type, Whether to use four-way shuttle car stereo library or stacker stereo library? Which automated stereo library storage solution is better?

Four way shuttle stereo warehouse

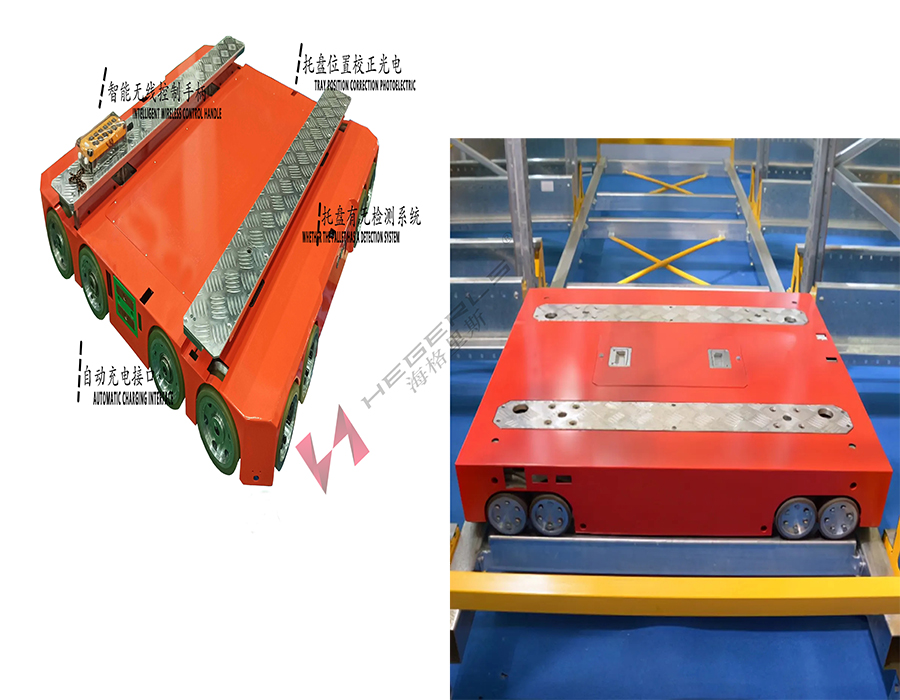

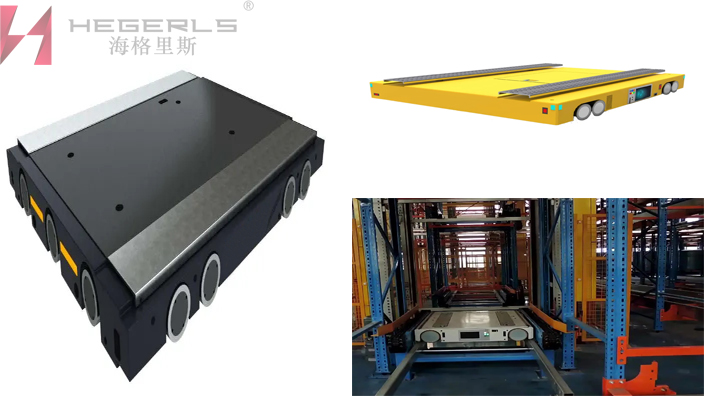

The four-way car rack is a kind of automated storage rack. It uses the vertical and horizontal movement of the four-way car to cooperate with the transfer of the elevator to achieve the purpose of storage automation. Among them, four-way vehicle, also known as four-way shuttle vehicle, is an intelligent handling device for pallet cargo loading and unloading. It is usually used in three-dimensional warehouses below 20M and can perform multi shuttle operations. It can move laterally and longitudinally along the predetermined track load, so as to realize the storage and retrieval of goods to the storage space of the shelf. The equipment can realize automatic cargo storage and retrieval, automatic lane change and layer change, automatic climbing, and ground handling. It is the latest generation of intelligent handling equipment integrating automatic stacking, automatic handling, unmanned guidance and other functions. The four-way shuttle has high flexibility. It can change the working roadway at will, and adjust the system capacity by increasing or decreasing the number of shuttle cars. If necessary, it can adjust the peak value of the system and solve the bottleneck of entry and exit operations by establishing the scheduling mode of the working team. The four-way shuttle stereoscopic warehouse can be designed according to the type of materials, and the volume ratio is generally 40%~60%.

Stacker stereo warehouse

As one of the typical automatic logistics storage equipment, the stacker is mainly divided into single core stacker and double column stacker. Three driving mechanisms are required for walking, lifting and pallet fork distribution. The vector control system and absolute address recognition system are used for full closed loop control, and the high precision of the stacker is achieved by using bar code or laser ranging to accurately identify the address. The stereoscopic warehouse stacker adopts single and double depth design, and the volume ratio of goods can reach 30%~40%, which can effectively solve the problem that the warehousing and logistics industry occupies a large amount of land and manpower, realize the automation and intelligence of warehousing, reduce the warehousing operation and management costs, and improve the logistics efficiency.

The differences between the application of four-way shuttle car and stacker in the automated stereo warehouse are as follows:

1) Different utilization rates of warehouse space

The four-way shuttle car rack is similar to the through rack in that it can realize intensive storage, which is also because the four-way shuttle car has one major advantage: it can directly reach any designated cargo space from the track; The stacker is different. It can only access the goods on both sides of the passage, so it can only be like a heavy shelf when planning. In this regard, in theory, the storage access rate of the four way shuttle and the stacker are different.

2) Different work efficiency

In practical application, the working efficiency of the four-way shuttle car automated stereo library is relatively lower than that of the stacker, mainly because the four-way shuttle car runs at a lower speed than the stacker. All the passage of the four-way shuttle must run in the planned route. Its steering requires a certain lifting of the body. The four-way shuttle also belongs to multi equipment linkage operation. The overall operation efficiency of the warehouse is more than 30% higher than that of the stacker; The stacker crane is different. It only operates in one lane between fixed tracks and cannot change the route. One stacker crane is responsible for one lane, and single machine operation can be carried out in this lane. Although its operation speed can be improved faster, the efficiency of the stacker crane limits the overall warehousing efficiency.

3) Differences in costs

In general, in the high-tech automated three-dimensional warehouse, each channel needs a stacker, and the cost of the stacker is high, which leads to the increase of the construction cost of the automated three-dimensional warehouse; The number of four-way shuttle auto stereoscopic library is selected according to the efficiency requirements of the overall warehouse. Therefore, in general, the cost of four-way shuttle auto stereoscopic library storage solution is lower than that of the stacker auto stereoscopic library.

4) Energy consumption level

The four-way shuttle generally uses a charging pile for charging. Each vehicle uses one charging pile, and the charging power is 1.3KW. 0.065KW is consumed to complete a single entry/exit; The stacker uses sliding contact wire for power supply. Each stacker uses three motors, and the charging power is 30KW. The consumption of the stacker for completing the once in/out storage is 0.6KW.

5) Running noise

The self weight of the stacker is large, generally 4-5T, and the noise generated during operation is relatively large; The four-way shuttle is powered by lithium battery, which is relatively light, so it is relatively safe and stable during operation.

6) Safety protection

The four-way shuttle car runs smoothly, and its body adopts a variety of safety measures, such as fire protection design and smoke and temperature alarm design, which are generally not prone to safety accidents; Compared with the stacker, it has a fixed track and the power supply is the sliding contact line, which generally does not cause safety accidents.

7) Risk resistance

If the stacker stereo warehouse is used, the entire roadway will stop when a single machine fails; Compared with the four-way shuttle car, when a single machine failure occurs, all the positions will not be affected by it. Other cars can also be used to push the faulty car out of the roadway, and four-way cars at other layers can be transferred to the faulty layer to continue to perform tasks.

8) Post scalability

For the three-dimensional warehouse of stackers, after the overall layout of the warehouse is formed, it is impossible to change, increase or decrease the number of stackers; Compared with the four-way shuttle bus, using the four-way shuttle bus stereo warehouse storage solution can also increase the number of shuttle buses, expand the shelves and other forms according to the later needs, so as to carry out the construction of the second phase of storage.

Another difference between the stacker stereo warehouse and the four-way shuttle car stereo warehouse is that the four-way shuttle car stereo warehouse belongs to the automatic dense high-rise shelf, with the rated load below 2.0T, while the stacker stereo warehouse belongs to the automatic narrow channel high-rise shelf, with the general rated load of 1T-3T, up to 8T, or even higher.

The suggestion given by HEGERLS is that if there is a high requirement for the storage rate of the warehouse, and it is also necessary to quickly implement the import and export of goods, it is safer to use the automated three-dimensional warehouse of the stacker; However, if there is a certain control requirement on cost or a certain requirement on the length of each channel, it is more appropriate to use the four-way shuttle auto stereoscopic library.

Storage system solution of HEGERLS intelligent shuttle bus

The HEGERLS intelligent shuttle bus storage system solution is a new generation of pallet shuttle bus storage solution launched by HGRIS. The solution consists of an intelligent shuttle bus, a high-speed elevator, a flexible conveyor line, a high standard goods storage facility and an intelligent warehouse management platform. Through standard solutions+standard configurable components, integrated delivery can be changed into product delivery, which can achieve overall high-quality and fast delivery.

Its advantages include high density, high efficiency, high flexibility, fast delivery, low cost, etc. The storage density is more than 20% higher than that of the stacker, the comprehensive operation efficiency is increased by 30%, the cost of a single cargo space is reduced by 30%, and the flexibility adapts to more than 90% of the new pallet storage and transformation scenarios, and can achieve 2-3 months of high-quality delivery.

Post time: Oct-08-2022