HEGERLS Intelligent Dense Storage Manufacturer | AGV Material Box Four way Vehicle Storage System Equipped with a Clamping Device Special Layer Changing Elevator

With the increasing demand from users, the logistics equipment industry has provided various intensive warehousing solutions such as drive in shelves, shuttle shelves, cantilever shelves, and crossbeam shelves according to market demand. However, it still cannot meet the operational needs of some enterprises for unmanned, intelligent, automated, and information technology. In order to meet market demand, the warehousing and logistics industry has also rapidly developed towards unmanned, automated, intelligent, and intensive directions in recent years.

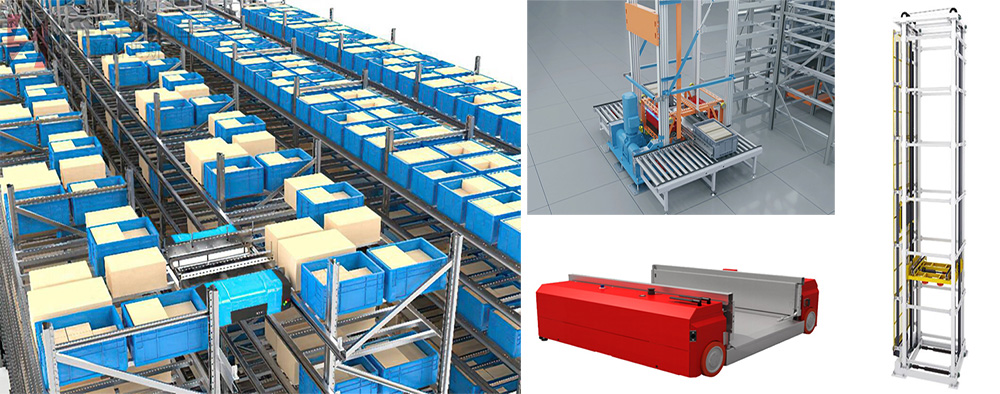

The material box type four way shuttle truck storage solution is an efficient and intelligent new type of intensive storage mode. It breaks the design concept of the three-dimensional warehouse stacker mode, greatly improves space utilization and access operation efficiency, facilitates system expansion, and has been widely applied in the market. The development of the Hebei Woke HEGERLS material box four-way shuttle system was initially mainly focused on the development of a "goods to person" sorting system, suitable for situations with multiple changes and sorting varieties. The Hebei Woke HEGERLS box type four way shuttle car is a combination of in situ track changing, automatic handling, three-dimensional configuration, and good scalability, fully suitable for unmanned warehouses.

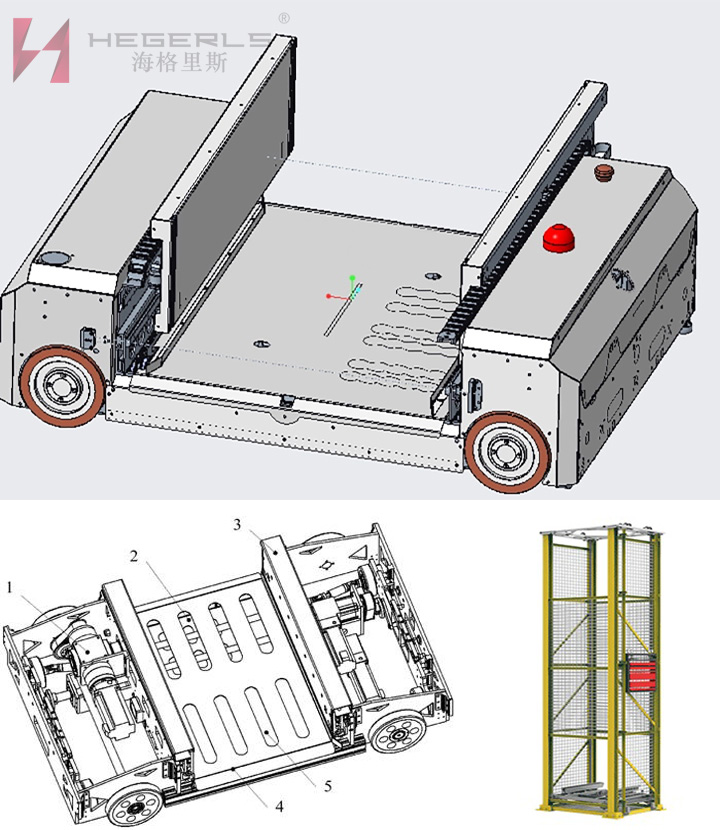

The HEGERLS material box four-way shuttle truck rack storage solution mainly consists of dense storage racks, elevators, high-speed cargo elevators, box type four-way shuttle trucks, drum conveyor lines, and central dispatch systems, suitable for rapid access to various containers. Relatively speaking, the four way shuttle system of the material box is much more flexible in operation, because after the unit becomes smaller and lighter, there are multiple ways to move the load. Of course, the simplest way is to use a fork. In order to improve storage density, double depth forks can be used, and the forks can also be changed in width to accommodate different widths of cardboard boxes. For the key accessory hoist in the four way shuttle car system of the material box, there are actually two typical structures, namely the hoist with a car and the hoist without a car. Among them, the car hoist is mainly used for changing layers of shuttle cars. Sometimes, to simplify the system, it can also be used to carry out operations every time, which will reduce work efficiency; Without a car hoist, there is a greater lifting capacity, and sometimes a dual station hoist can be used, with an hourly lifting capacity of over 200 times or even higher. In order to improve work efficiency, the speed of the small car will be as high as 5m/s. Due to the use of a clamping device, the acceleration of the small car can reach 2m/s2, which greatly improves the work efficiency of the small car. For a hoist, the lifting speed is generally above 4m/s to match the efficiency of the entire system.

Innovation of HEGERLS Box Type Four Way Shuttle

The mechanical structure, controller, and software of the HEGERLS box type four-way shuttle car are all self-developed by Hebei Woke. It adopts a supercapacitor power supply method, with a charging and discharging life of millions of times, greatly improving charging efficiency, reducing charging time, increasing standby time, and improving the utilization rate of the HEGERLS material box four-way shuttle car. Compared with other products, the HEGERLS material box four-way shuttle car has a height of only 325mm, and the middle material box position can meet the transportation requirements of (≤ 600) * 400 * (≥ 200) mm goods. The reduction and lightness of equipment units also means a significant improvement in operating speed and acceleration. At the same time, the floor area is also smaller, allowing for arbitrary layout in the upper and lower space of the shelves, which can be widely used in sub industries such as e-commerce, 3C, intelligent manufacturing, medical, clothing, etc.

Moreover, the inbound and outbound processing capacity of the HEGERLS box type four-way shuttle truck is 3-4 times that of the stacking machine's three-dimensional warehouse. In terms of path planning, the system adopts the S-curve algorithm. Based on the destination location, the shuttle can automatically plan the acceleration distance, uniform speed distance, and deceleration distance to accurately reach the target location at the fastest speed and in the shortest time.

Hebei Woke Metal Products Co., Ltd. is a comprehensive logistics solution provider, providing system planning and integration services for various industries, including automated three-dimensional warehouses, intelligent four-way vehicle dense warehouses, automated material box handling robot systems, automated conveying and sorting equipment, warehouse information management software, logistics containers, and other logistics equipment. Our company integrates independent design and development, production and manufacturing, and technical services, specializing in the manufacturing and sales of various efficient, environmentally friendly, energy-saving, and intelligent four-way shuttle cars, elevators, material box handling robots, various AGVs, two-way shuttle cars, stackers, as well as various industrial shelves, pallets, plastic turnover boxes, conveyors, warehouse cages, and other warehousing equipment and turnover container products. At the same time, in combination with our self-developed warehousing management software WMS WCS forms a fully automated intelligent warehousing system, suitable for various large warehouses, refrigerated warehouses, production workshops, and various types of enterprise warehouses. Our production factory is equipped with professional mechanical processing equipment such as various machine tools, large plate shearing machines, bending machines, rolling mills, laser cutting machines, and automated spraying assembly lines, providing sufficient guarantee for product quality and delivery time. To serve different industries and at different stages of the supply chain, by providing customers with internationally advanced logistics management technology, experience, and high-quality logistics related systems, and through continuous logistics improvement, we assist customers in achieving established customer service levels while reducing their total logistics costs, thereby improving the logistics capabilities of enterprises and core market competitiveness.

Post time: May-31-2023