Project Name: automated stereoscopic Library (as/rs)

Project start time: early April 2022

Project completion time: mid June 2022

Project construction area: Yancheng, Jiangsu, East China

Project partner: a new energy battery manufacturing Co., Ltd. in Yancheng, Jiangsu

Customer demand: the enterprise is a new energy battery manufacturing company. The warehouse of the company is mainly used to store some materials required for manufacturing lithium batteries and some molding materials. The process of manufacturing lithium batteries is cumbersome and requires a lot of materials, which means that the use of manual operation requires a lot of labor, and the efficiency of manual work can not meet the standards of the enterprise. In this regard, in order to improve the internal situation of the warehouse and reduce the labor force in the warehouse as much as possible, so as to reduce the cost of the enterprise, the customer found our Hebei Walker metal products Co., Ltd. (independent brand: hegris hegerls) and hoped that our company could provide one-stop warehousing services such as design, formulation, production, manufacturing and construction of the company’s warehouse according to their requirements.

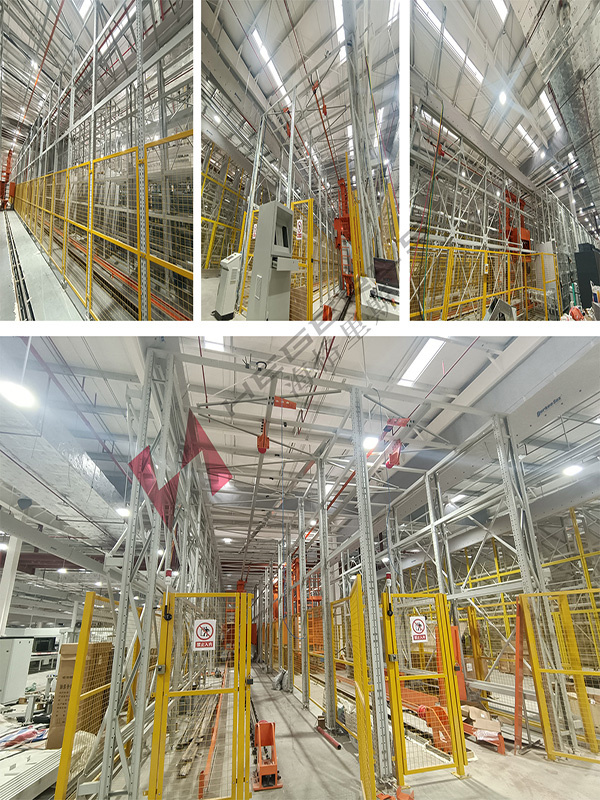

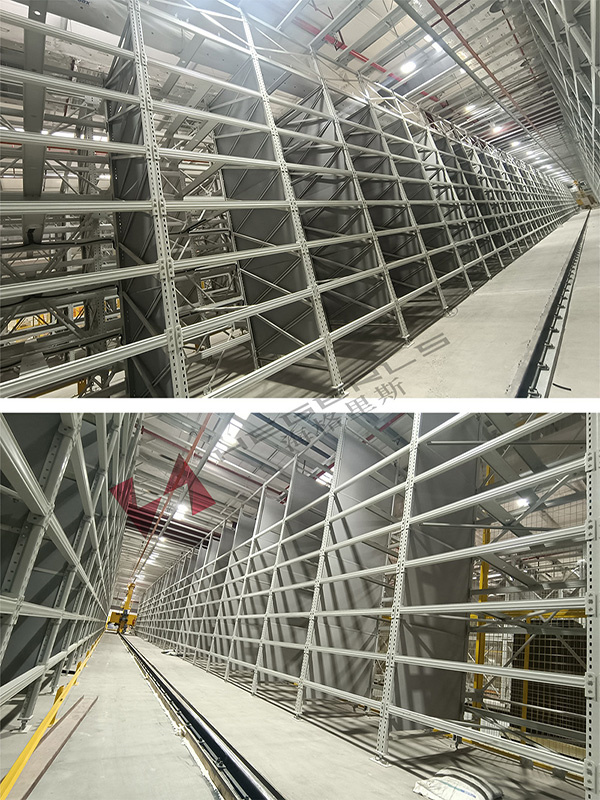

Project implementation: the customer had the basic idea and direction when they found our company. After communication with our company, and in order to meet the standards expected by the customer as much as possible, our company arranged professional technicians to visit the other company. After investigation, we found that the company has a large number of materials and a large warehouse. In order to better reduce labor consumption, we finally developed a clear design scheme. The overall scheme is as follows: the entire intelligent automation three-dimensional library needs to establish four libraries, namely, platinum material library, structural parts library, self discharge library and test library. The structural parts library needs to be designed and constructed as four tunnels, and the platinum material library needs to use two tunnels. At the same time, considering the size of the warehouse, our company has planned to use multiple groups of high-rise shelves, multiple stacker three-dimensional warehouse taking and placing systems, AGV automatic handling systems and other supporting storage equipment and facilities, so as to ensure that the warehouse can maximize its space utilization.

Project summary: as/rs is a very large project, and the requirements for details in installation are also very strict. From the beginning of installation to the later commissioning, our technicians are personally responsible for tracking and inspecting the as/rs project of the intelligent automated three-dimensional library for more than two months. At present, it has been officially put into use and successfully completed the acceptance. At the same time, it has received very high satisfaction in the later customer experience.

Project implementation process:

With the explosive growth of the new energy industry, the demand for new energy batteries is rising, and the cost and performance requirements are also rising. The new energy industry is full of opportunities and challenges. In particular, the degree of automation and intelligence of battery production lines directly determines the competitiveness of new energy enterprises. Therefore, equipment automation upgrading has become the only way to enhance the competitiveness of new energy enterprises. Now the industry is developing in the direction of safety and standardization. High precision, high efficiency, serialization and high automation production lines of equipment have become the general direction of development. Fully automated and intelligent production equipment will ensure high consistency, high reliability, safety and straight through yield of products on the basis of ensuring the production process, so as to improve the comprehensive benefits of the enterprise. Among them, automated three-dimensional warehouse, as a modern logistics facility, undoubtedly plays an important role in improving the storage automation level of enterprises. Just like this, Hebei hegris hegerls warehouse proposes to put into use the intelligent automated three-dimensional warehouse according to the needs of customers in Yancheng, Jiangsu!

Intelligent automatic stereo library as/rs function

Intelligent automatic stereoscopic warehouse as/rs can store various types of materials efficiently and reasonably under the high command of computer management system; Provide all items to all departments accurately, in real time and flexibly, and provide accurate information for material procurement, production scheduling, planning, production and marketing connection, etc. At the same time, the automated three-dimensional warehouse also has the functions of saving land, reducing labor intensity, improving the working efficiency of enterprises, reducing storage and transportation losses, and reducing flow costs.

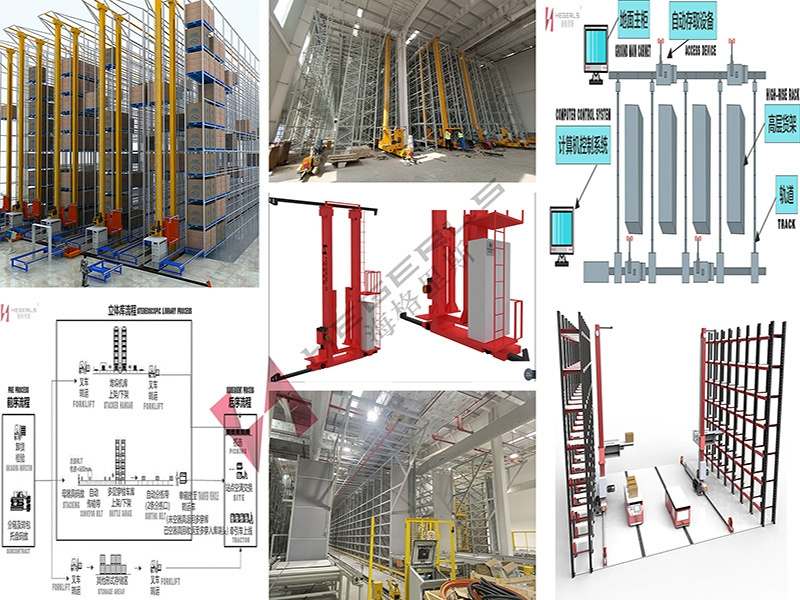

Intelligent automatic stereoscopic library as/rs workflow

The working process of the intelligent automated three-dimensional warehouse as/rs developed and built by Hebei hegris hegerls storage for a new energy battery manufacturing Co., Ltd. in Yancheng, Jiangsu Province is as follows:

1 warehousing process

The warehouse is provided with a warehousing terminal in each warehousing area and a finished product warehousing platform at each lane crossing. For the finished products to be warehoused, the warehoused terminal staff will type in the name, specification, model and quantity of the items, and then the control system will receive the warehoused data through the human-computer interface. According to the principles of uniform distribution, first down, then up, heavy and light at the bottom, warehoused nearby and ABC classification, the management calculator will automatically allocate a storage space and prompt the warehoused lane. According to the prompt, the staff can send the items loaded on the standard pallet to the storage platform of the roadway by the small battery truck of supporting equipment and facilities; The monitor instructs the stacker to store the pallets in the designated location.

Note: there are two types of stock in processing of inventory data: first, the staff should input the name (or code), model, specification, quantity, stock in date, production unit and other information on the stock in tray on the stock in client through the human-computer interface after the stock in of the goods; The second is warehousing through pallets.

2 delivery process

The bottom end is the finished product delivery area. The central control room and the terminal are respectively equipped with delivery terminals. LED display screens are set at each lane intersection to prompt the exit number of the goods to be delivered to the assembly platform. For finished products to be delivered from the warehouse, after the staff type in the product name, specification, model and quantity, the control system will find out the pallets that meet the delivery conditions and have the same or slightly more quantity according to the principles of first in first out, nearby delivery and delivery priority, modify their corresponding account data, and automatically send all kinds of finished product pallets to the delivery desk at each lane entrance, which will be taken out by the battery truck and delivered to the destination. At the same time, the issue system generates an issue document on the client after completing the issue operation.

3. Processing flow of empty disk returned to warehouse

After some empty pallets from the bottom floor are manually stacked, the staff type the empty pallet return operation command, and then the staff will send them to a certain Lane crossing on the bottom floor with a battery truck according to the prompt. The stacker will automatically return the empty pallets to the original entrance of the three-dimensional warehouse, and then each workshop will pull away the empty pallets to form a certain turnover.

Intelligent automatic stereoscopic library as/rs is mainly equipped with equipment and facilities

1 tray

All goods adopt unified and standardized pallets to improve interchangeability and reduce standby. The pallet can meet the loading and unloading of stacker, forklift and other equipment, and can also meet the operation on the conveyor.

2 high shelf

The high-rise shelves adopt special combined shelves and beam structure. The shelf structure is beautiful and generous, material saving and practical, and easy to install and construct. It belongs to an optimized design structure.

3 roadway stacker

According to the characteristics of the warehouse of a new energy battery manufacturing Co., Ltd. in Yancheng, Jiangsu Province, the stacker adopts the structure of lower support, lower drive and two side columns. The stacker operates in the three coordinate directions of X, y and Z in the roadway of the high-rise shelf, stores the products located at the storage platform at each lane entrance into the designated goods grid, or transports the goods in the goods grid out to the storage platform at the lane entrance. The design and manufacture of stacking mobility used by hegerls is carried out in strict accordance with national standards, and the structural strength and rigidity are accurately calculated to ensure the smooth, flexible and safe operation of the mechanism. The stacker equipped by hegerls has a safe operation mechanism to prevent the occurrence of accidental phenomena. The operating speed is 4-80mm/min (variable frequency speed regulation), the lifting speed is 3/16mm/min (two speed motor), the fork speed is 2-15mm/min (variable frequency speed regulation), the communication direction is infrared, and the electronic mode is sliding contact wire mode.

4 computer management, monitoring and dispatching system

The computer management, monitoring and dispatching system can reasonably allocate and log in all the warehousing operations of the automated three-dimensional warehouse, and make statistical analysis of its data, so as to realize the preferential control of logistics, minimize the occupation of inventory and capital, and accelerate capital turnover. In the daily access work, especially in the off-site picking operation, it is inevitable that there will be article access errors, so the inventory must be carried out regularly. Inventory processing verifies the accuracy of inventory item data through the actual inventory of each pair of items, and timely corrects inventory accounts to achieve the unification of accounts and materials. The stacker will not perform other types of operations during the inventory period. During operation, the stacker will issue a complete inventory order to the stacker in a certain roadway, and the stacker will transport the goods in this roadway to the outside of the roadway one by one in sequence. The goods will not be loaded onto the stacker. After receiving the order to return to the warehouse, the stacker will return this tray of goods to its original position and take out the next tray of goods, and push it in this way until all the tray items in this roadway are counted, Or enter the normal working state after receiving the inventory suspension command from the management system. If the laneway receives the inventory temporary residence command before the inventory is completed, continue to complete the inventory operation after receiving the new command.

Project application effect:

1) On the basis of sub regions, the unified dispatching management of materials in the new energy industry has been realized;

2) It effectively integrates storage resources and improves the management level of enterprise storage;

3) Railed multi lane stacker +agv automatic handling, realizing unmanned storage;

4) Integrating flexibility and flexibility, it has built a material warehouse that meets the needs of the new energy industry.

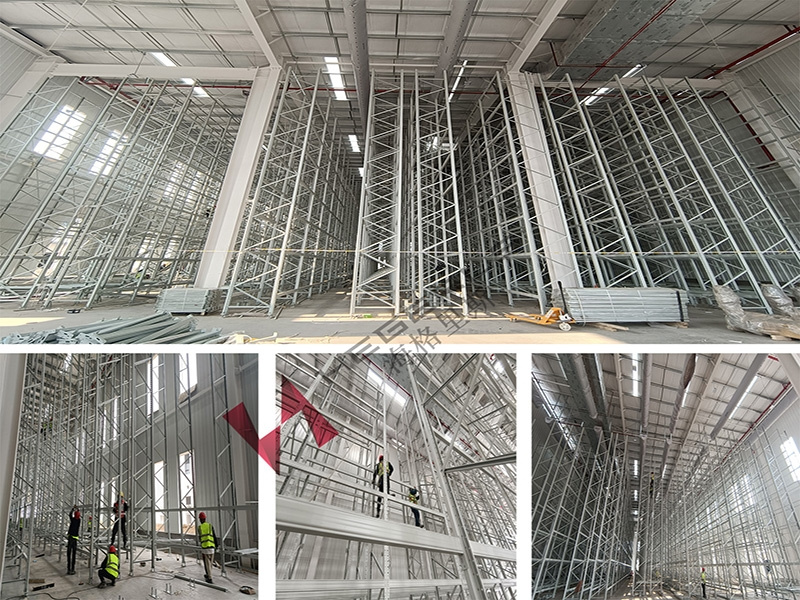

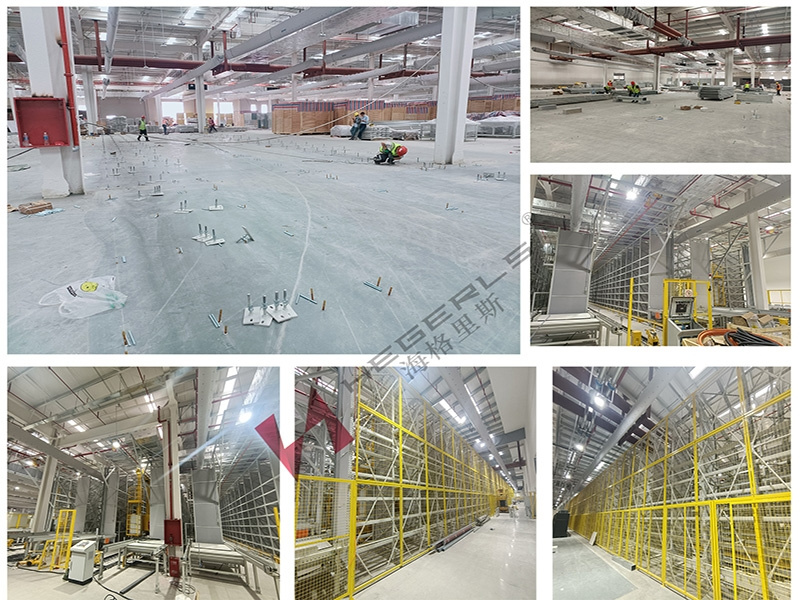

Site shooting of project construction photos:

Post time: Jun-24-2022