china heavy duty double sided cantilever rack system for MDF pipe warehouse storage

HEGERLS cantilever racking

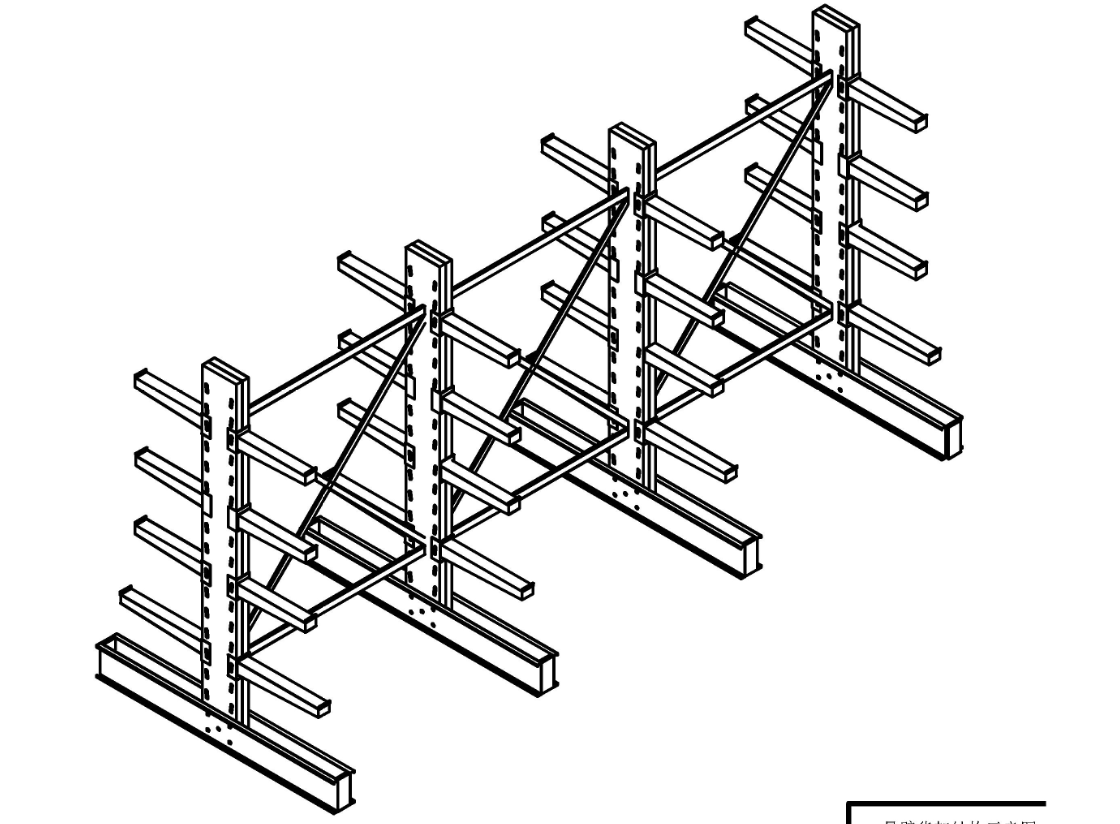

Heavy Duty Cantilever Racking System with the technical lateral forklift can solve the storage of long material and irregular shaped material. The highest column can reach 10 meters, cantilever arm length is 1.0 – 1.2m, and loading capacity can reach 1 ton.

Heavy Duty Cantilever Racking System can be used in indoor and outdoor. It can be used hot dip galvanized to surface treatment of outdoor. It also can be installed ceiling at the top of the column, then can be resisted wind, rain and sunshine.

Cantilever racking adopt specific upright and high-strength arms, suitable to store long-shaped,circular,plates and irregular heavy materials. According to capacity of load carrying, they are divided into light, medium and heavy styles.

After increasing steel or wooden layer board on the arms, it is particularly suitable for small space and lower height warehouse, with high space usage. It is very convenient and fast to load and unload the goods, with easy view of goods storage.

Features & Benefits

◆ Wide range of load capacities suiting both standard and seismic applications

◆ Center column design creates unlimited horizontal space

◆ Fully customizable

Details Introduction

Arms can be adjusted easily up and down the column and are available in length with a variety of capacities from 220 ~ 1,500 kgs (100 ~ 3,300 lbs).

The arm of a cantilever racking can be either a single side or a double side.

We provide HEGERLS cantilever racking 2021 high quality 1500kgs with power coating for tube or MDF storage. We devote ourselves to warehouse storage field for 25 years experience. We are expecting become your long term partner in China.

HEGERLS cantilever racking 2021 high quality 1500kgs with power coating for tube or MDF storage

1.Product introduction of cantilever rack

Heavy Duty Cantilever Racking System with the technical lateral forklift can solve the storage of long material and irregular shaped material. The highest column can reach 10 meters, cantilever arm length is 1.0 – 1.2m, and loading capacity can reach 1 ton.

Heavy Duty Cantilever Racking System can be used in indoor and outdoor. It can be used hot dip galvanized to surface treatment of outdoor. It also can be installed ceiling at the top of the column, then can be resisted wind, rain and sunshine.

Cantilever racking adopt specific upright and high-strength arms, suitable to store long-shaped,circular,plates and irregular heavy materials. According to capacity of load carrying, they are divided into light, medium and heavy styles.

After increasing steel or wooden layer board on the arms, it is particularly suitable for small space and lower height warehouse, with high space usage. It is very convenient and fast to load and unload the goods, with easy view of goods storage.

2.Product parameter.

3.Product feature and application

3.1.It is suitable for MDF and tube storage. The loading of each arm could reach 1000kgs

3.2 the height of post could reach 10m high

4.Production detail of cantilever rack

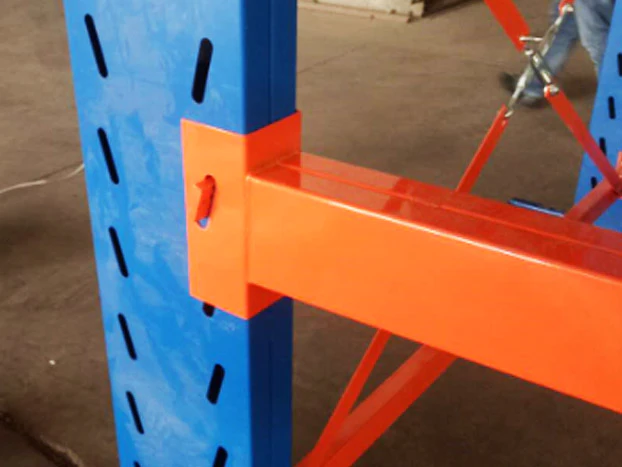

4.1 The color could be customized. We have color of blue and orange. It could also be customized.

4.2 the holes are formed by laser cutting. It is exactly

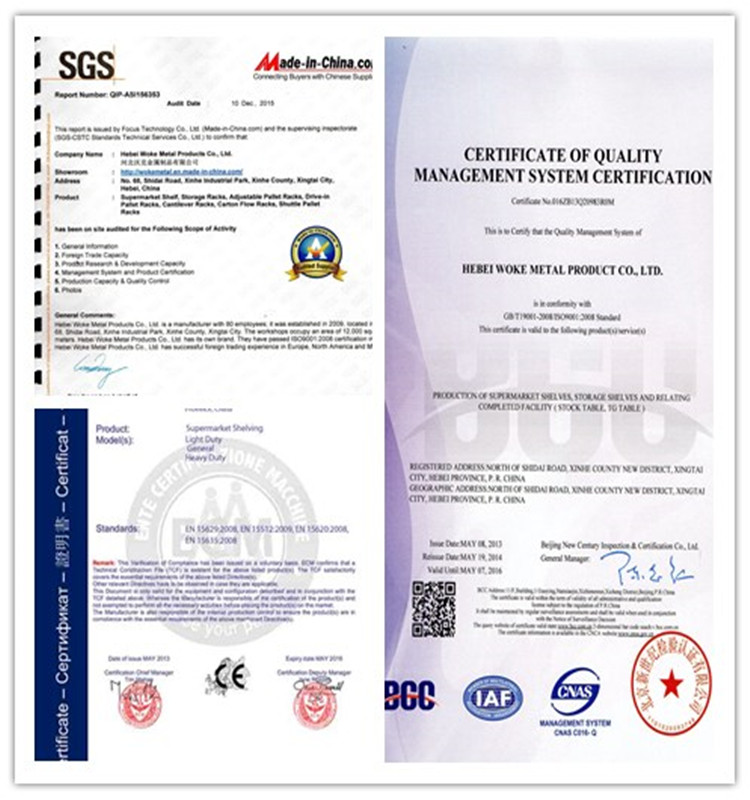

5.1 we have passed the certificate of SGS.BV,TUV and ISO quality control certificate.

Furthermore, we also have passed the certificate of environment management, health and safety management

5.2 Raw materials: cold rolled steel Q235B. or international steel standard SS400

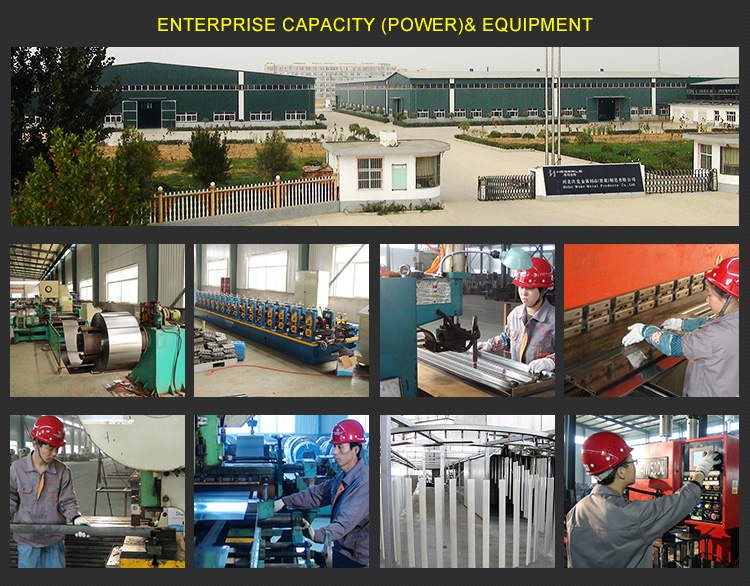

5.3. rolling machine. We have 12 sets rolling line, could roll different size.

5.4 Power coating line. It is 500 meters long and the brand of power coating gun is GEMA, which is very famous on the coating field.

5.5 customer visiting. Our location is in hebei province, near to Beijing and Tianjin. Our airport name is Shijiazhuang zhengding international airport. Welcome your visiting any time.

5.6 exhibition. Every year we will attend canton fair and shanghai Cemat fair.

6 Delivery. Shipping and service

6.1 Packaged and shipping. Normally, the upright will be packed by plastic foams. And shuttle racking will be loaded into wooden pallets.

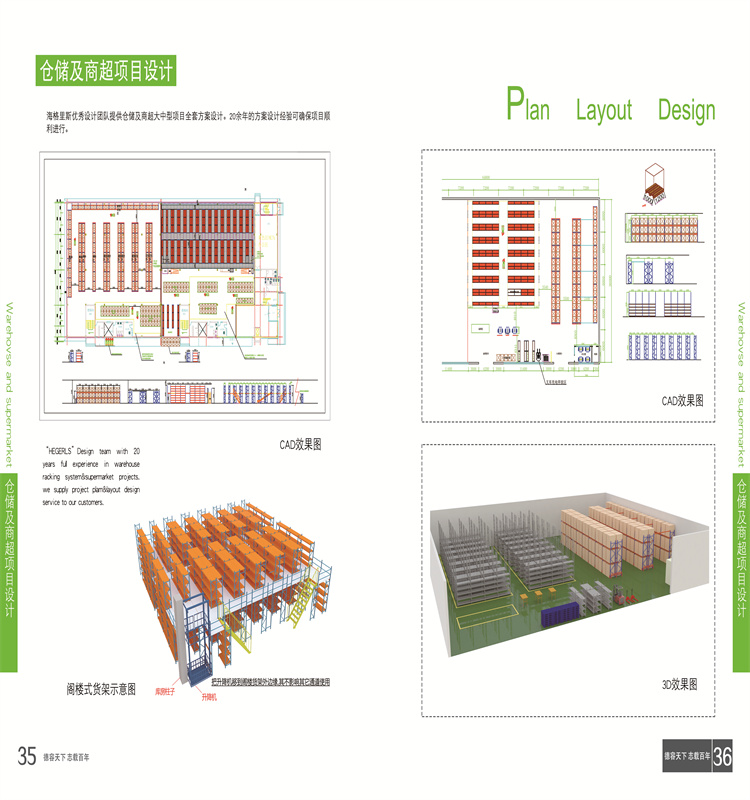

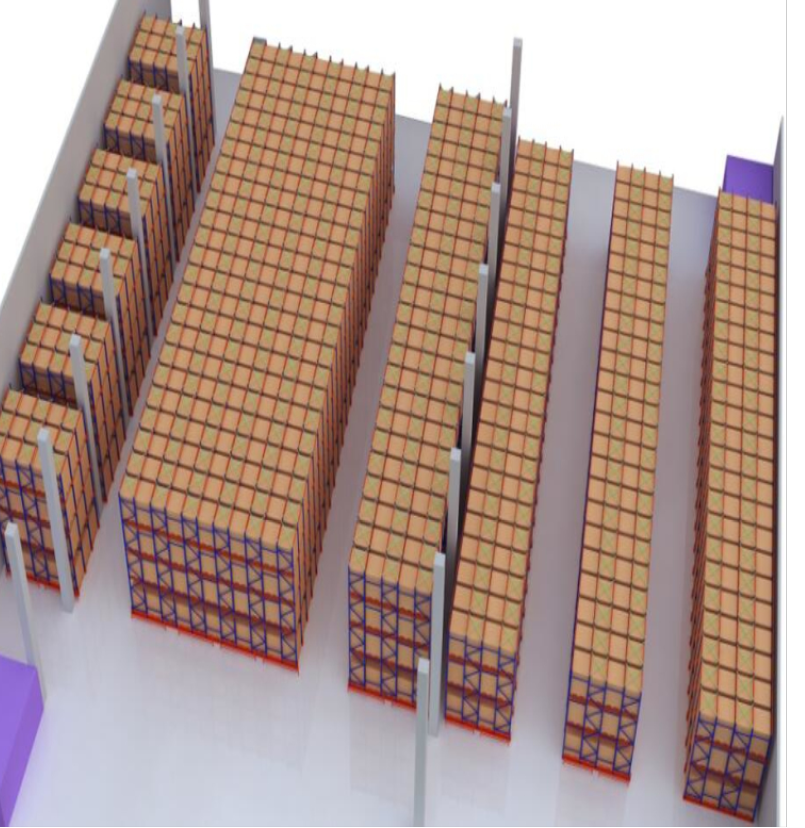

6.2 We provide layout drawing and 3d effect picture

FAQ

Q: What is the quality warranty of your products ?

A: Our quality warranty is 1 years. We will keep on providing the service out of this time and only offer cost of spare parts.

Q: What is the lead time ?

A: For the racking system, it normally take 30 days. And for the shuttle racking, it need 60 days for the production.

Q:Could you provide the layout design ?

A: Yes, we could provide the layout design freely in Autocad or 3d picture. It is our free service.

Q:What color cold be available ?

A: Normally, we have color of blue RAL5005 and orange RAL2004. The color could also be customized. Please provide us your color number.

Q:how about the installation?

A: We will provide the detailed installation drawing. For the simple traditional racking, the workers could install it according to our drawing. Or else, our engineer could go to on site to instruct the installation And buyer will afford the cost.

8.Latest news

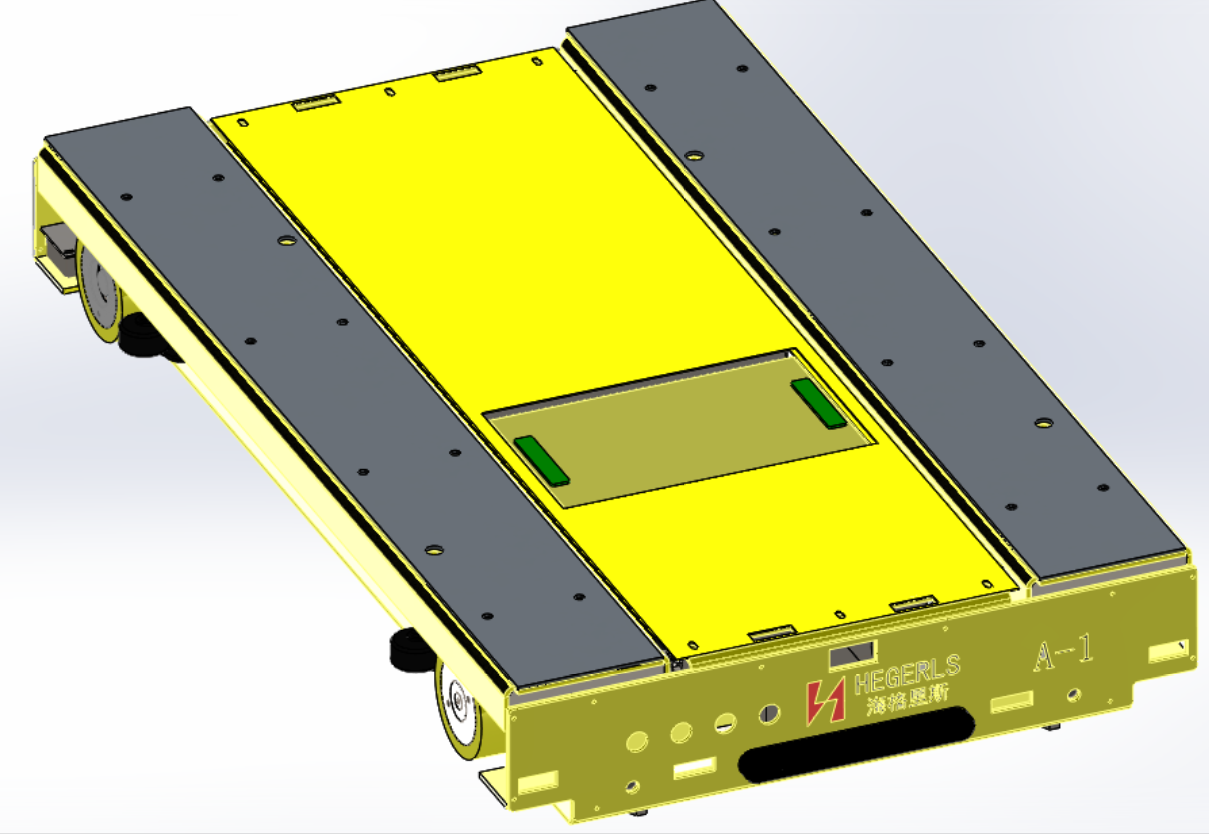

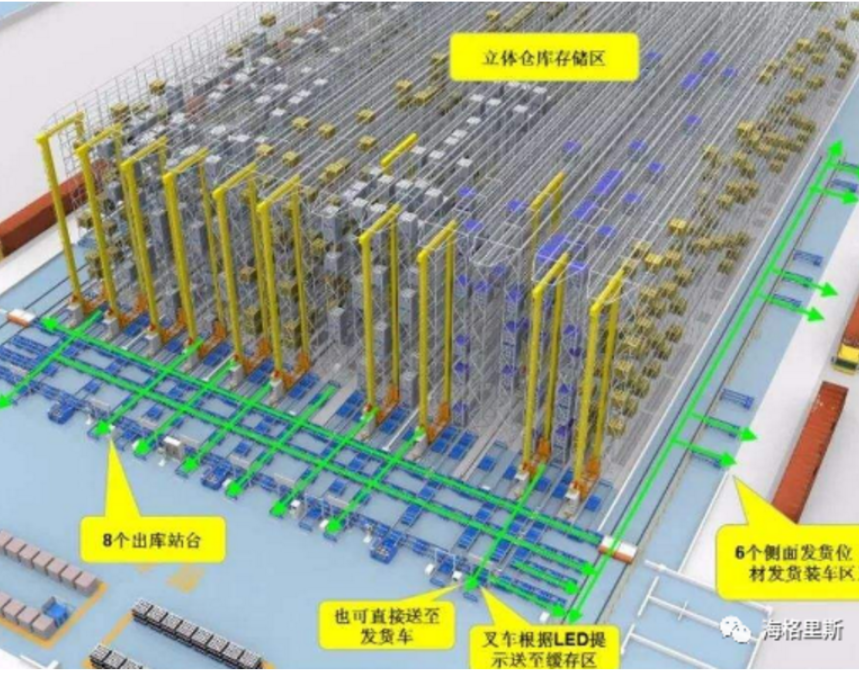

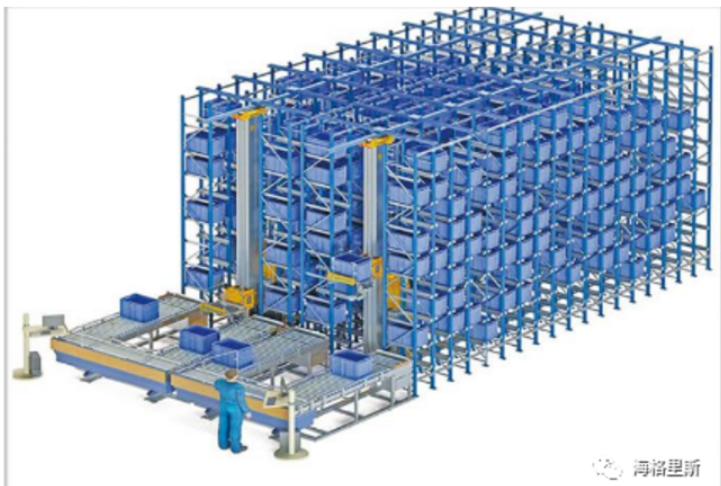

The core equipment of automated warehouse-stacker

Tracked roadway stacking crane is a special crane developed with the appearance of the three-dimensional warehouse, referred to as the stacker, is a very important lifting and handling equipment in the three-dimensional warehouse, and is a symbol of the characteristics of the three-dimensional warehouse. Its main purpose is to run along the track in the roadway of the high-rise warehouse to store the goods at the entrance of the roadway into the cargo compartment; or to take out the goods in the cargo compartment and transport it to the entrance of the roadway to complete the warehousing operation.

There are many types of stacker cranes. In the current three-dimensional warehouse applications, the most common is

1. According to the structure, it is divided into single column structure and double column structure

2. According to the running track classification, it is divided into linear type and curved type

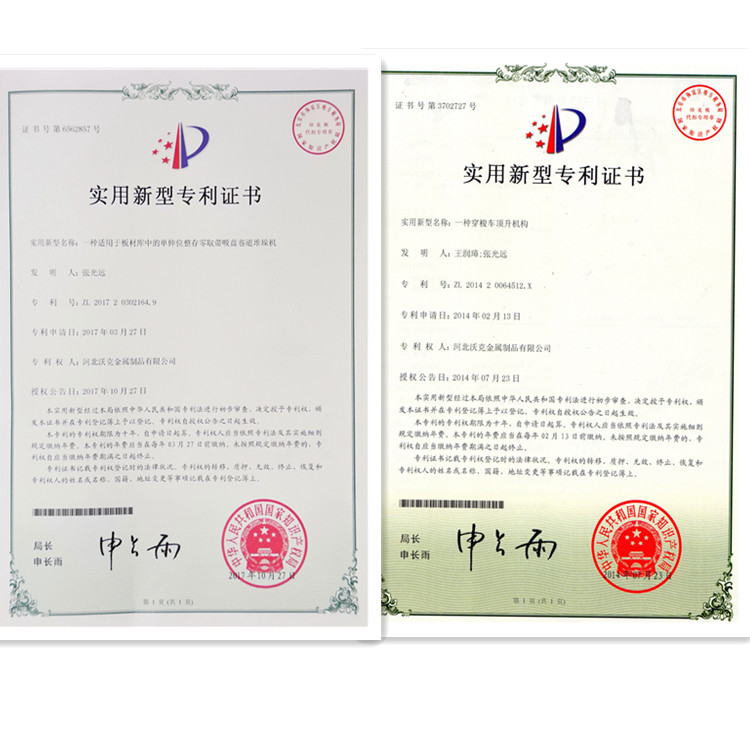

At present, in my country's three-dimensional warehouses, stackers are widely used in industries such as machinery manufacturing, automobile manufacturing, textile industry, railways, cigarettes, and medicine. With the development of modern industrial production, the technology of tracked roadway stacker cranes is constantly improving and perfecting. Since 2017, Hegerls has obtained the new shape and new function stacker patent. It has continued to summarize experience and is committed to development and practicality. We have been very serious about building a three-dimensional warehouse for new products with safety and security!

techical equipments.

Package and loading

Exhibition booth

Customer visiting

Free Layout drawing design and 3D picture

Certificate and patents

Warranty

Normally it is one year. It could also be extended.